Product Description:

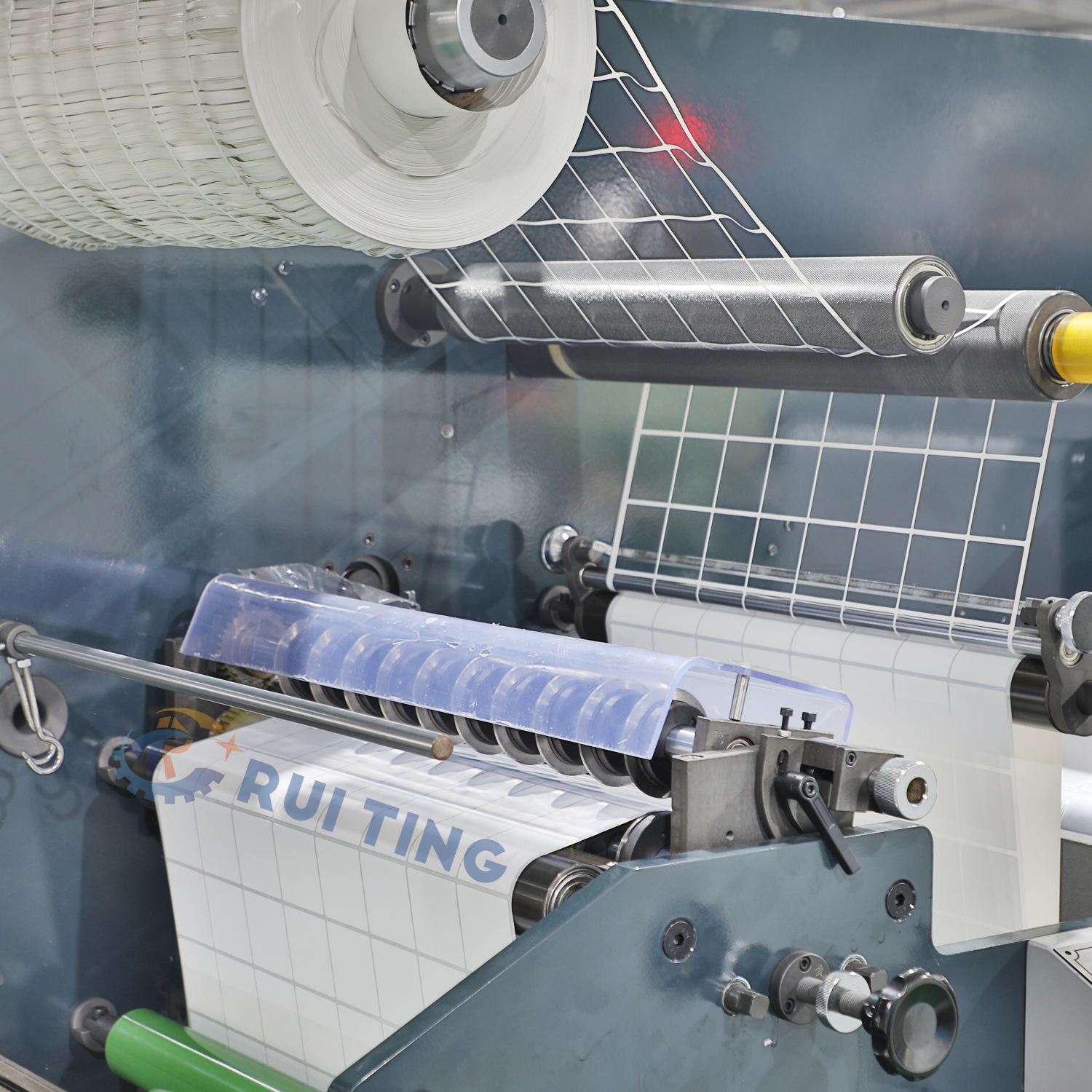

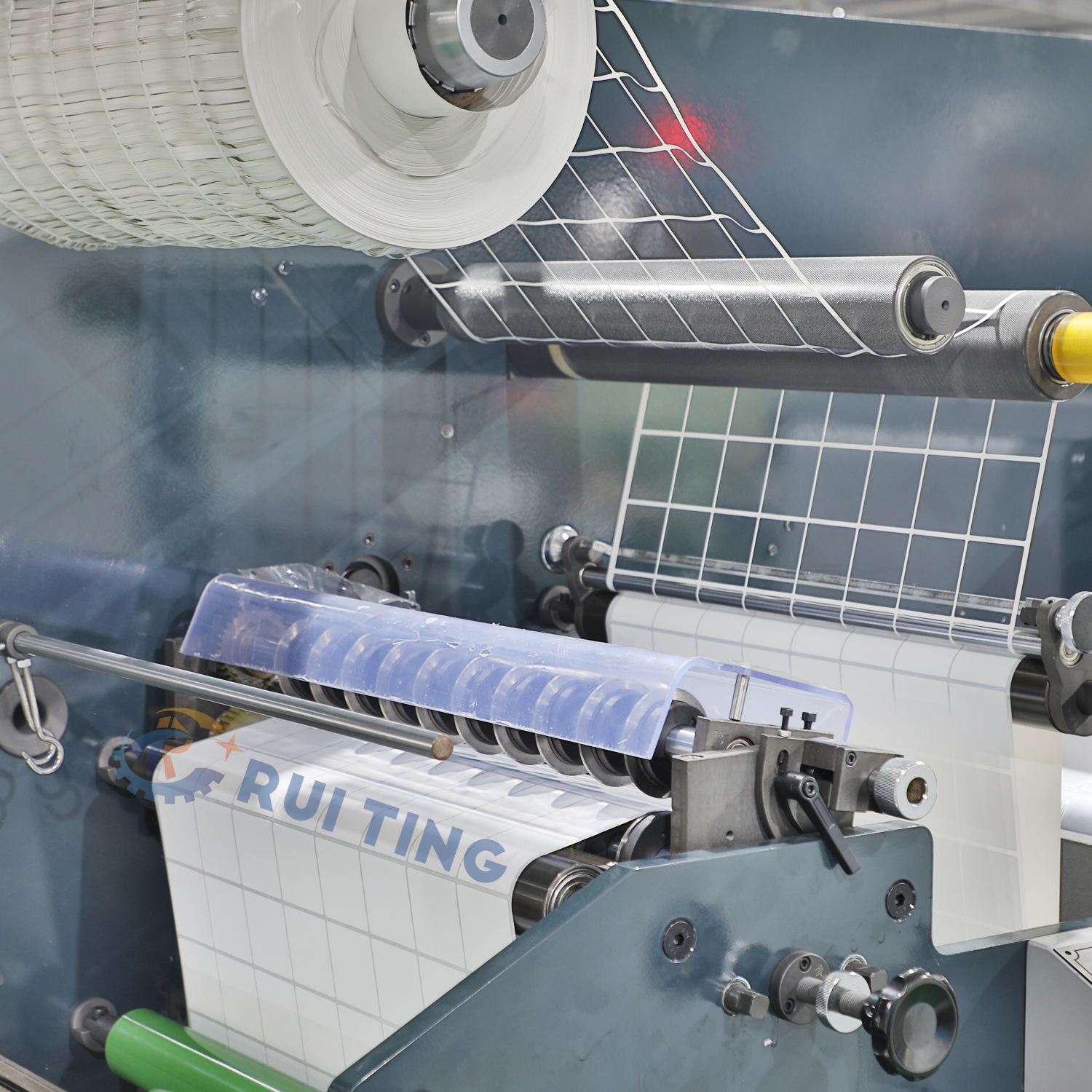

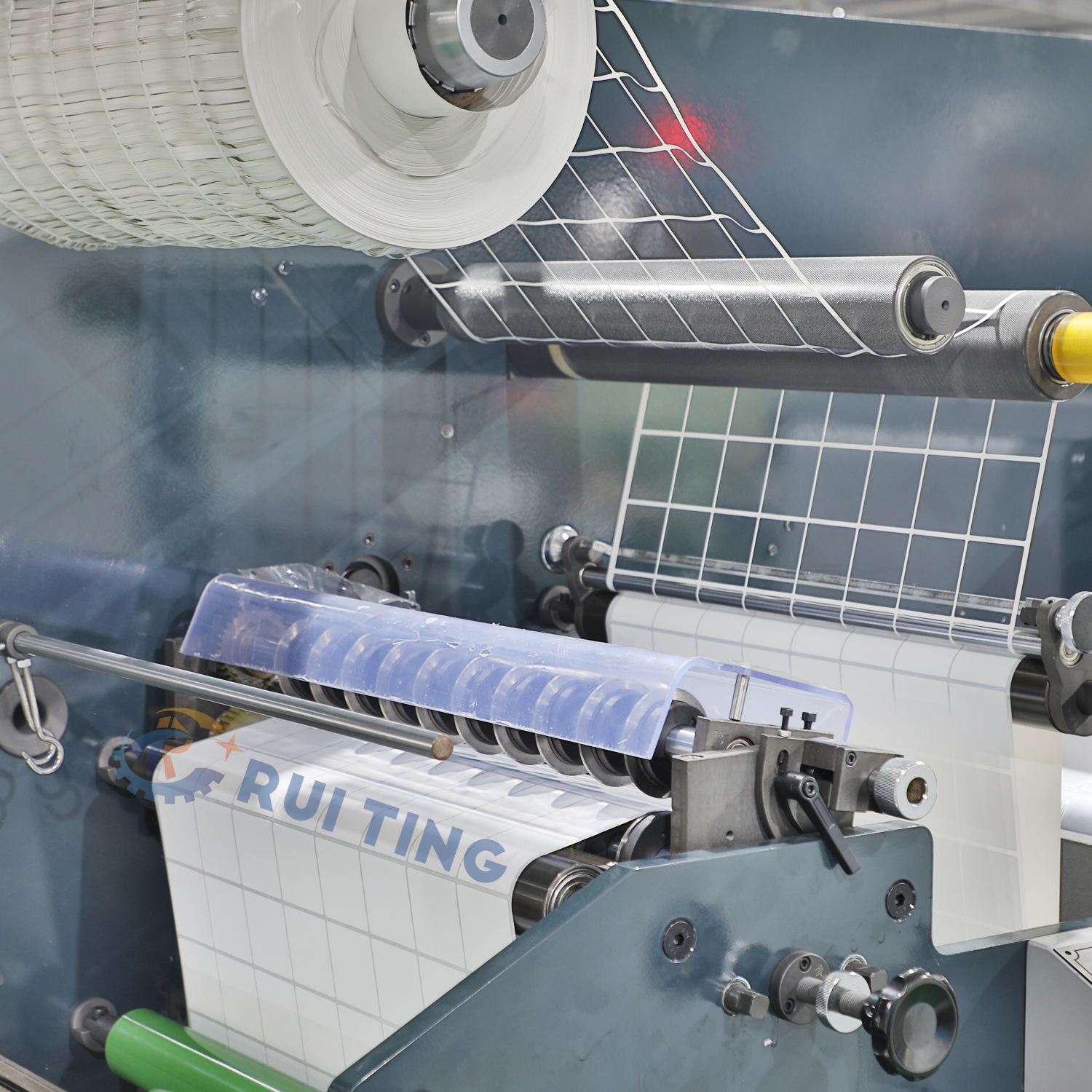

Introducing the Rotary Label Die Cutting Machine, a state-of-the-art solution designed for high-volume label production. Engineered with precision and efficiency in mind, this machine is the epitome of modern manufacturing technology tailored for the label industry. Its robust construction and user-friendly interface make it an indispensable asset for businesses looking to streamline their production process.

Product Advantages:

High-Performance Operation: The machine have electronic web guide for impeccable material alignment, ensuring each label is cut to perfection.

Ease of Use: With a single-operator design, this machine simplifies the production workflow, reducing labor costs without compromising on output.

Versatility: Capable of handling a variety of label materials, this machine is not limited to adhesive labels but also adept at processing thermal transfer tapes, barcode stickers, and more.

Advanced Features: Equipped with a mechanical spring-loaded brake and clutch for controlled unwinding and rewinding, and a label count/meters count system for precise batch production.

Product Features:

Electronic Web Guide: For accurate material tracking and alignment.

Mechanical Spring Loaded Brake & Clutch: Ensures smooth operation and material control.

Batch Counting and Control: With a preset counter for batch over stop, maintaining production quotas is effortless.

Movable Slitting Trolley: Offers adaptability in slitting operations to meet diverse label specifications.

Adjustable Core Mandrel: Compatible with core sizes ranging from 1" to 3" for versatile roll handling.

Duplex Rewinding Station: Enhances productivity by allowing simultaneous rewinding of two label rolls.

Product Applications:

The machine finds its niche in a wide array of applications, making it an ideal choice for:

Adhesive Label Production: For creating labels used in various industries, including food and beverage, cosmetics, and pharmaceuticals.

Thermal Transfer Tape Conversion: Ideal for producing tapes used in thermal transfer printers for durable barcodes and logos.

Barcode Sticker Manufacturing: Precise cutting for high-quality barcode stickers essential for inventory management and tracking.

Inkjet and Printed Labels: Capable of handling rolls of labels printed with specific designs or information for branding and informational purposes.

Data Sheet:

Slitting speed | 150m/min |

Max. web width | 420mm |

Max.cutting width | 410mm |

Die-cutting length | 178mm-476mm |

Max. unwinding diameter | 500mm |

Max. rewinding diameter | 500mm |

Cutting precision | ±0.1mm |

Total power | 8 KW |

Power voltage | 380V,3 Phase |

Overall dimensions | 3.5m*1.50m*1.85m |

Machine weight | 2100kg |

Machine detial:

Customer feedback: