Product Description:

The Flexographic Printing Machine is a sophisticated, fully-automatic press engineered to deliver high-precision printing for a variety of applications, including labels, flexible packaging, and more. This machine is equipped with state-of-the-art technology to ensure a seamless operation from unwinding to rewinding.

Product Advantages:

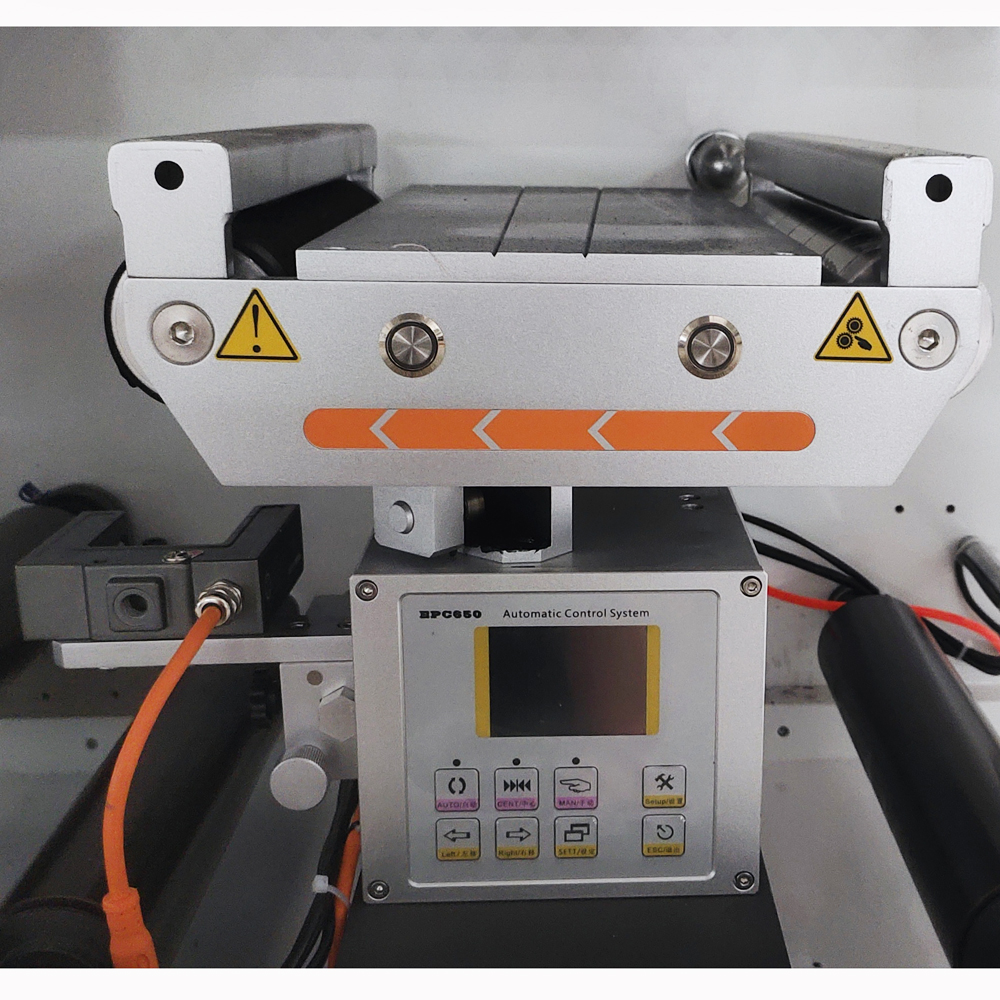

Automated Web Guidance: An electronic induction paper web guide device for automatic and continuous correction of paper position, minimizing deviations.

Efficient Changeovers: An electronic crane for swift and effortless changes of magnetic cylinders of different specifications, saving valuable production time.

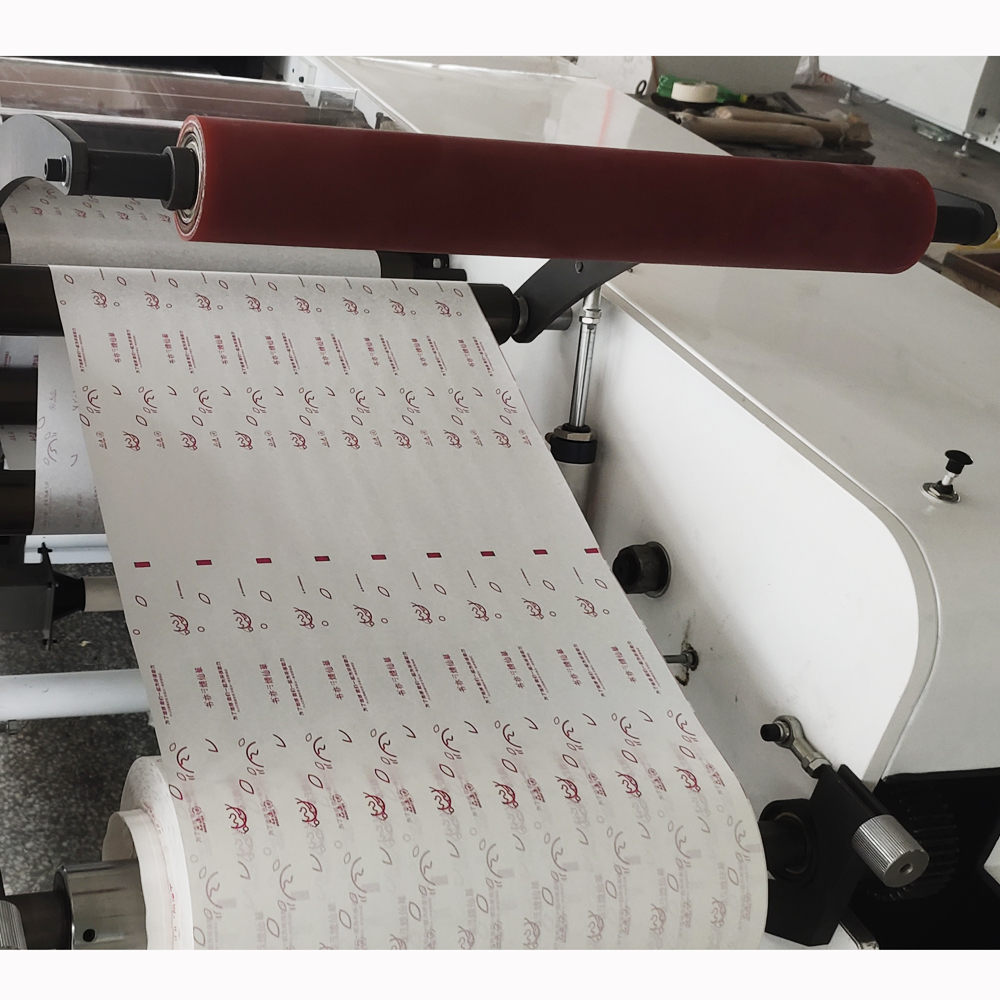

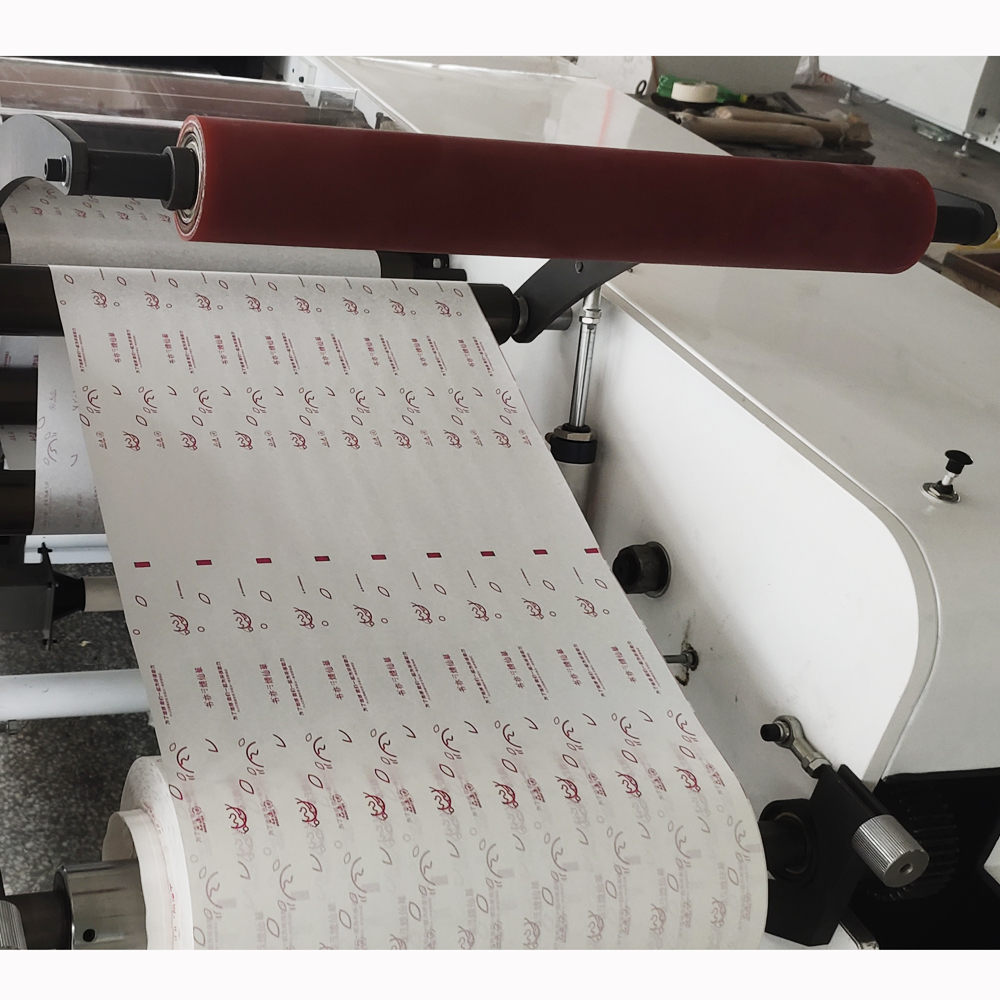

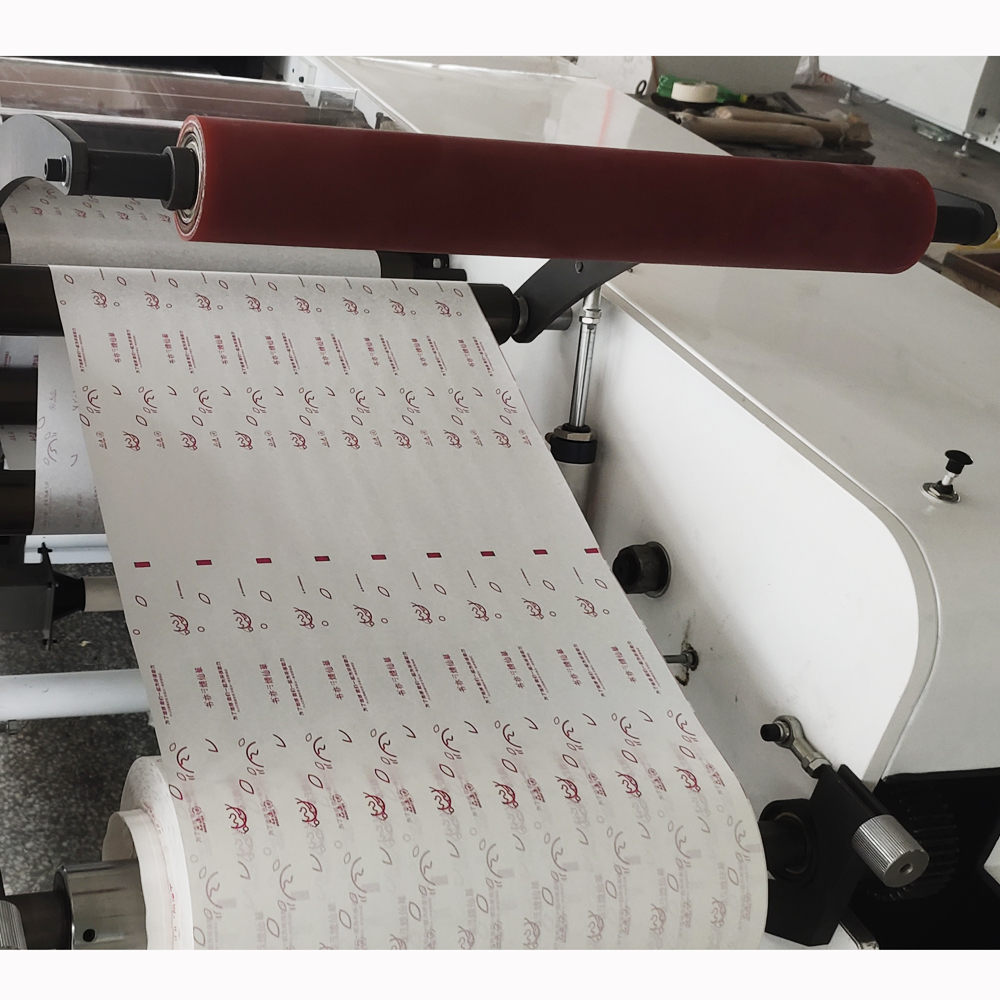

Enhanced Print Quality: A combination of flexographic color groups and ceramic anilox rollers ensures uniform ink distribution and vibrant print output.

Real-time Monitoring(option): An integrated video inspection system allows for on-the-fly print quality checks, reducing waste and improving efficiency.

Product Features:

Unwinding Unit: Features a paper splicing platform and pneumatic lifting for smooth operation.

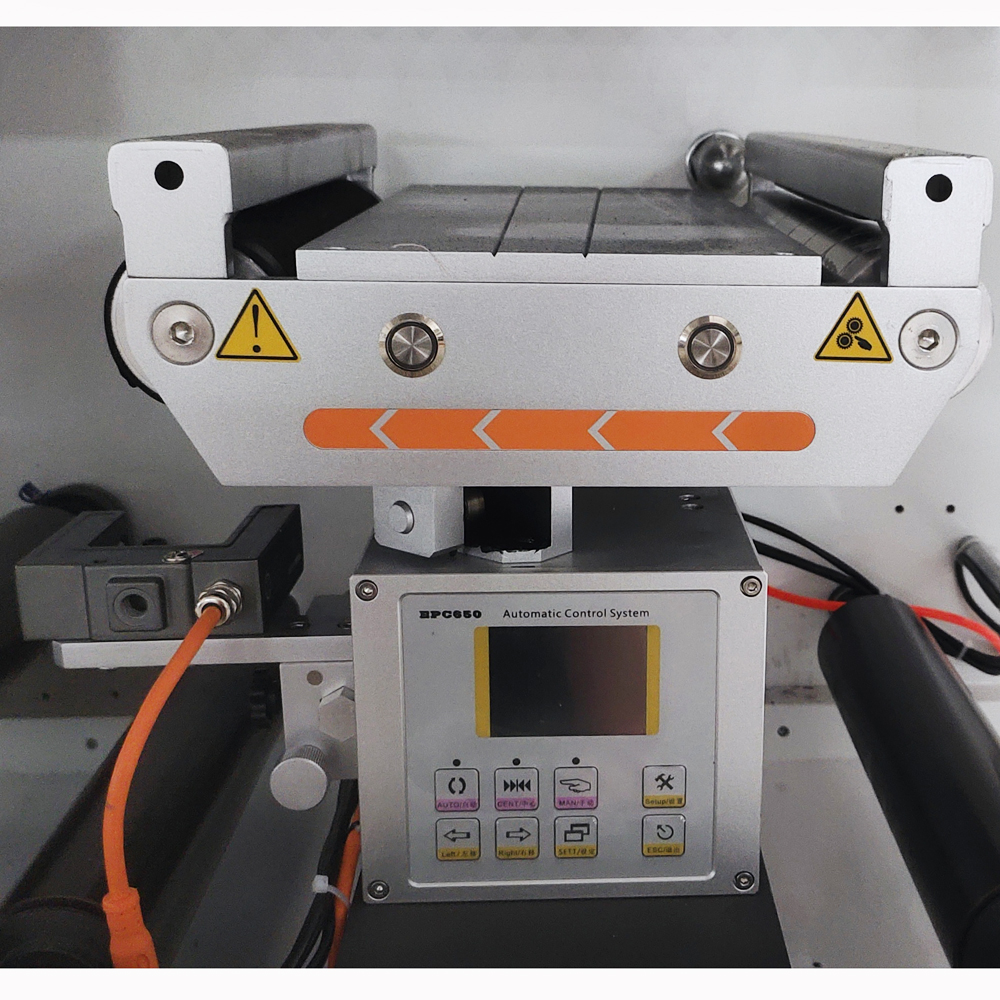

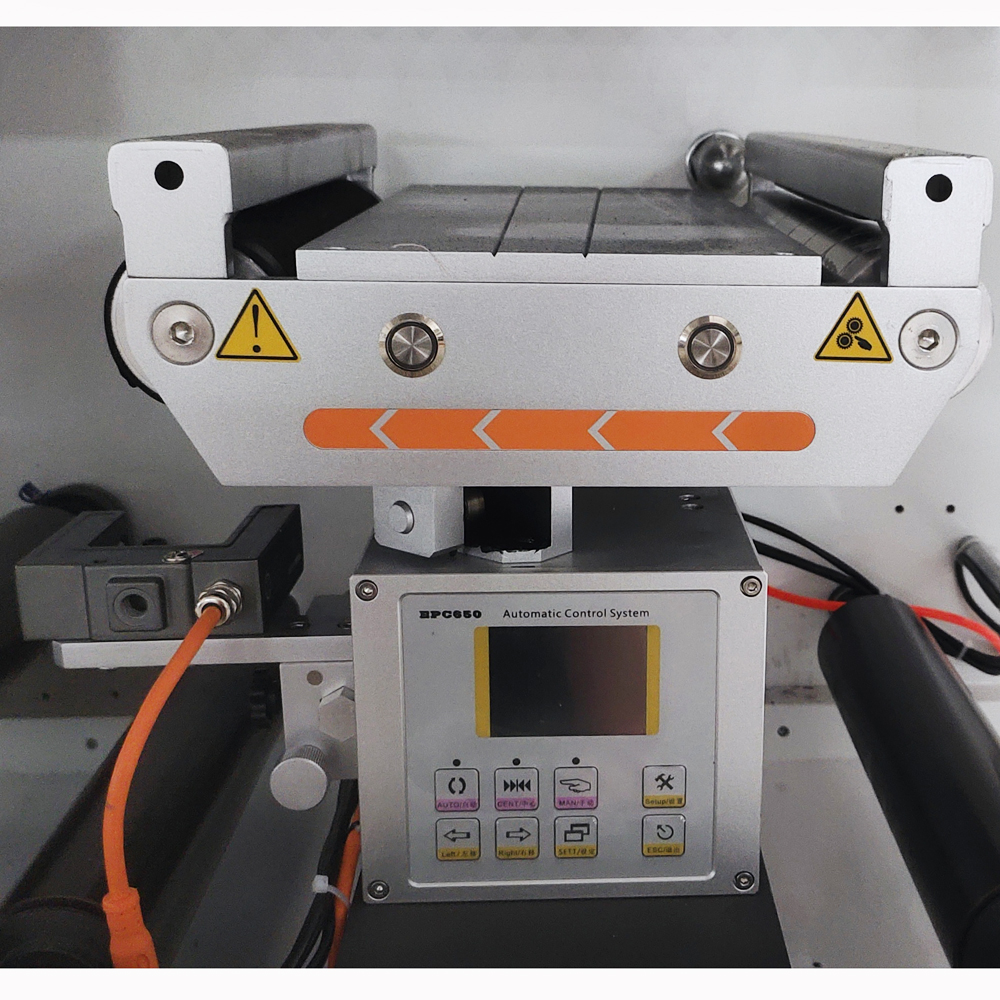

Web Guide System: An electronic device that corrects any slight deviations in the paper web running.

Printing Unit: High-precision rollers and ceramic anilox with helical gear for consistent print quality.

Drying System: Equipped with an infrared heating system that is adjustable and controllable individually.

Die Cutting Unit(option): Uses a circular pressing method with interchangeable rollers for versatile die-cutting capabilities.

Slitting Unit(option): Utilizes a circular knife method, synchronously linked with the host machine for precise slitting.

Rewinding Unit: Incorporates a magnetic powder brake and automatic tension control for stable and accurate rewinding.

Product Applications:

Suitable for a wide range of substrates such as PE film, aluminum foil, and paper, this machine is ideal for industries requiring high-quality labels, packaging, and flexible material printing.

Product Transportation:

While specific details on transportation are not provided, it can be expected that the machine would be securely packaged and shipped using appropriate heavy-load handling equipment to ensure safe delivery.

Data Sheet:

Printing speed | 60m/minute |

Printing color number | 3+3 color |

Max width of paper | 620mm |

Max printing wide | 620mm |

Max unwinding diameter | 600/1000mm |

Max rewinding diameter | 600/1000mm |

Printing length | 175-380mm |

Precision of overprint | ±0.15mm |

Overall dimension | 5.4(L)×2.1(W)×2.25(H)m |

Weight | about 4500kg |

Machine detial:

Customer feedback: