Product Description:

The state-of-the-art 2-Shaft Turret Rewinding Machine is a marvel of modern engineering, designed to streamline the production of labels and similar materials. With its integrated automatic paper tube feeder and advanced control system, this machine sets a new standard in efficiency and precision.

Product Advantages:

High Efficiency: The non-stop operation and automatic features reduce downtime and increase production rates.

Versatility: Interchangeable rewinding shafts accommodate a range of roll sizes, making the machine adaptable to various job requirements.

Automated Processes: From core gluing to label rewinding, the machine handles multiple steps automatically, reducing manual labor and potential for error.

Integration Capability: Seamlessly connects with other equipment for a fully automated production line.

Product Features:

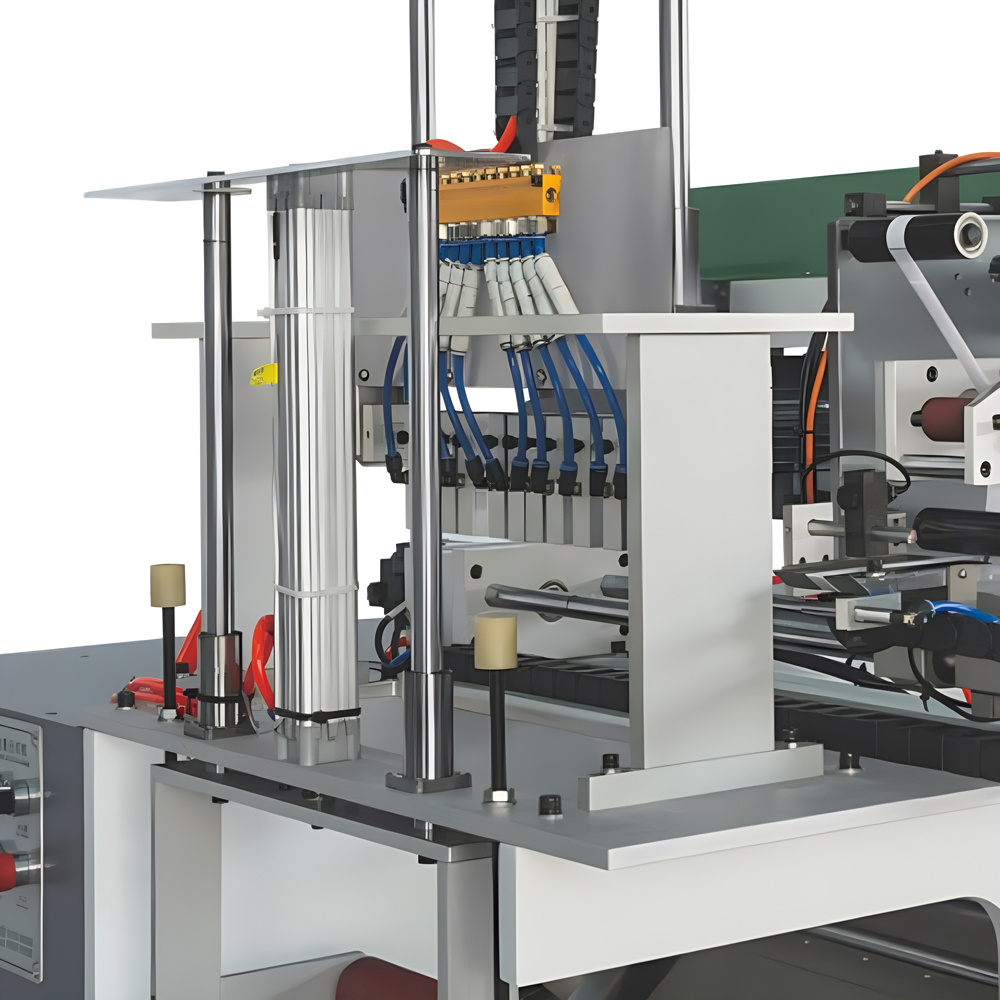

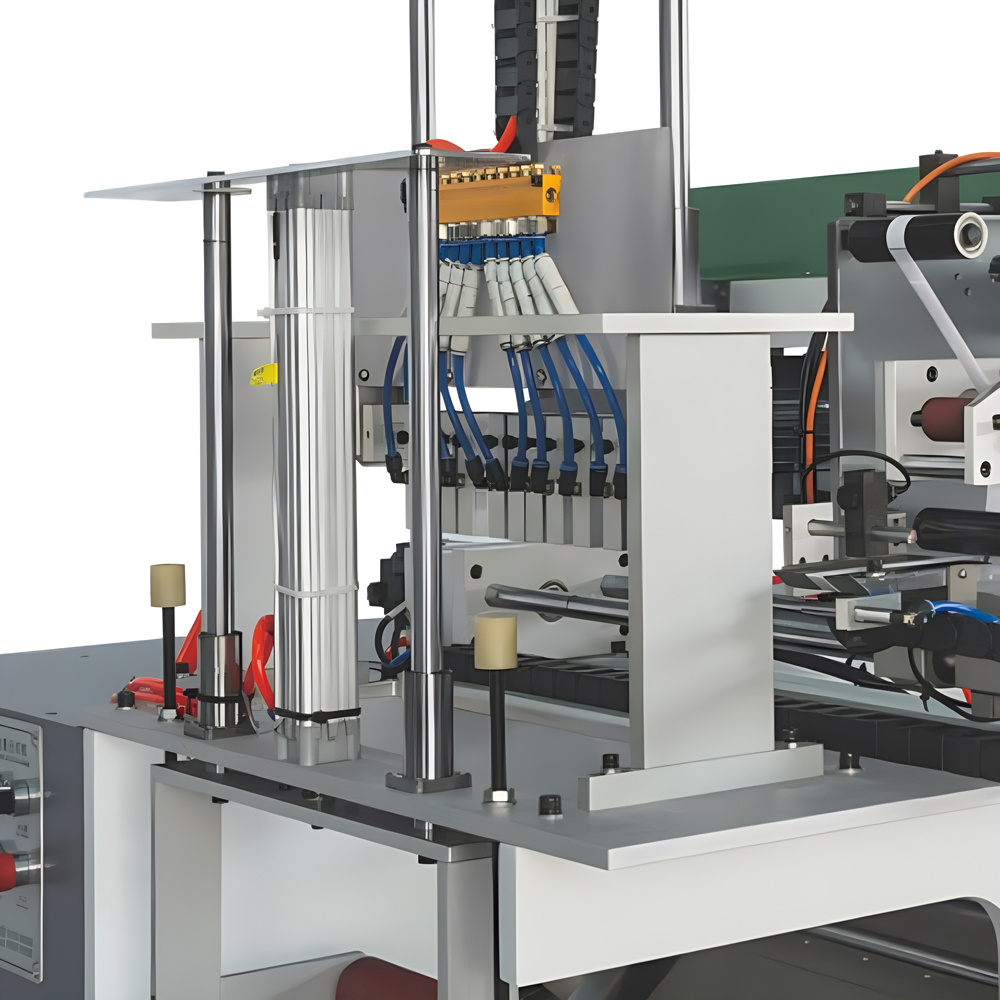

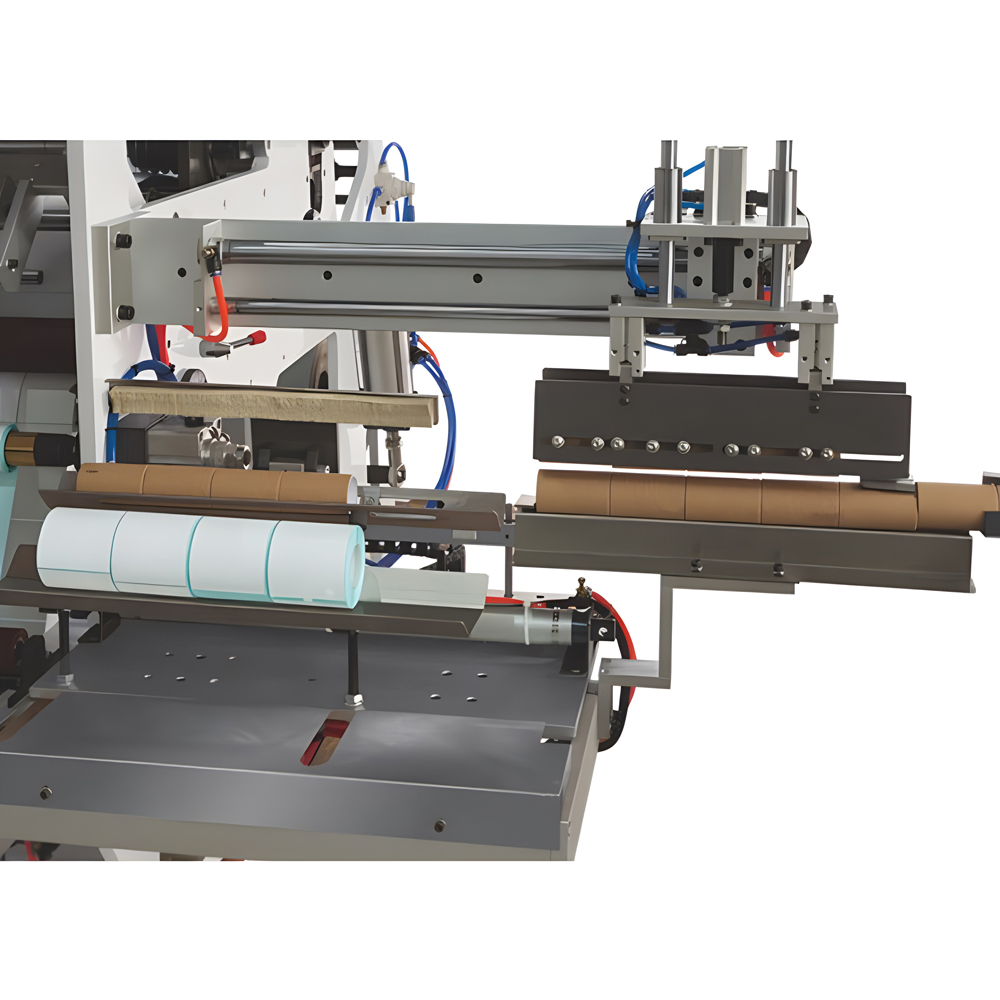

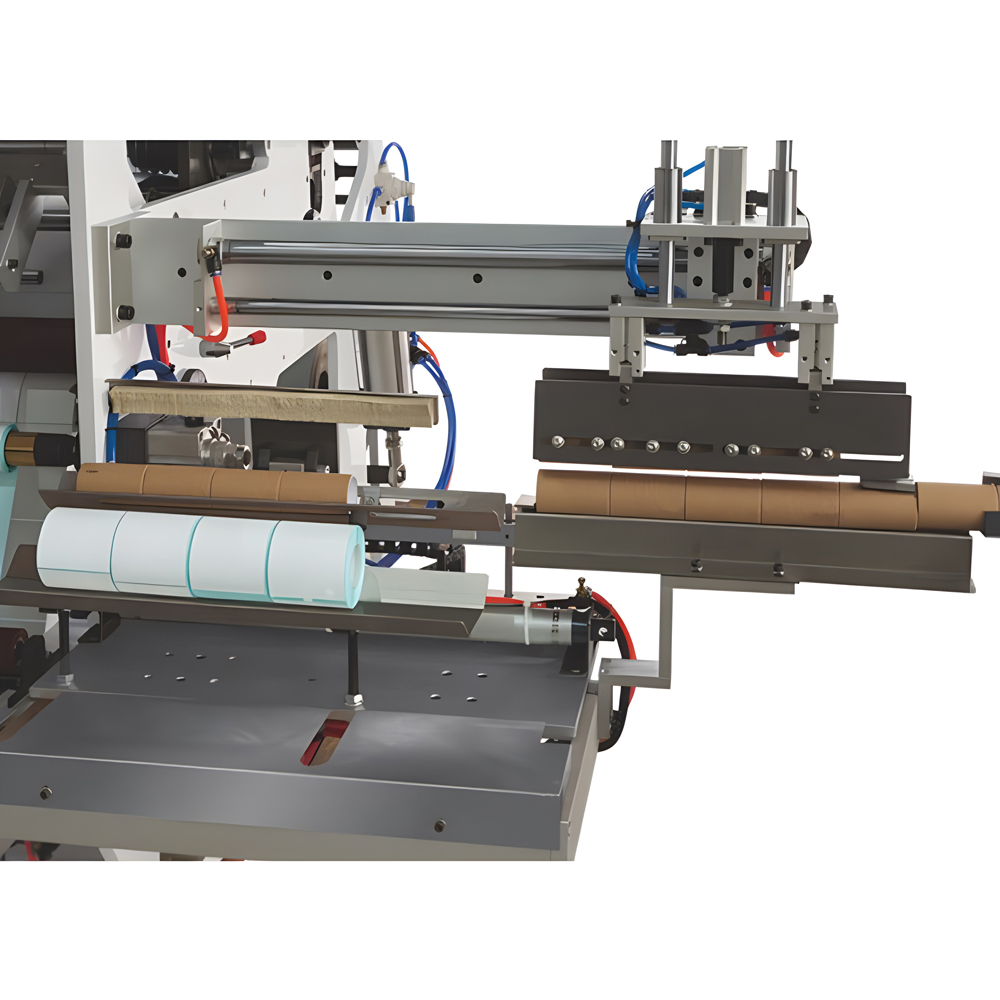

Automatic Paper Tube Feeder: Ensures a continuous supply of paper tubes for uninterrupted production.

Conveyor Belt System: Smoothly transports paper tubes to the rewinding area, enhancing the feeding process.

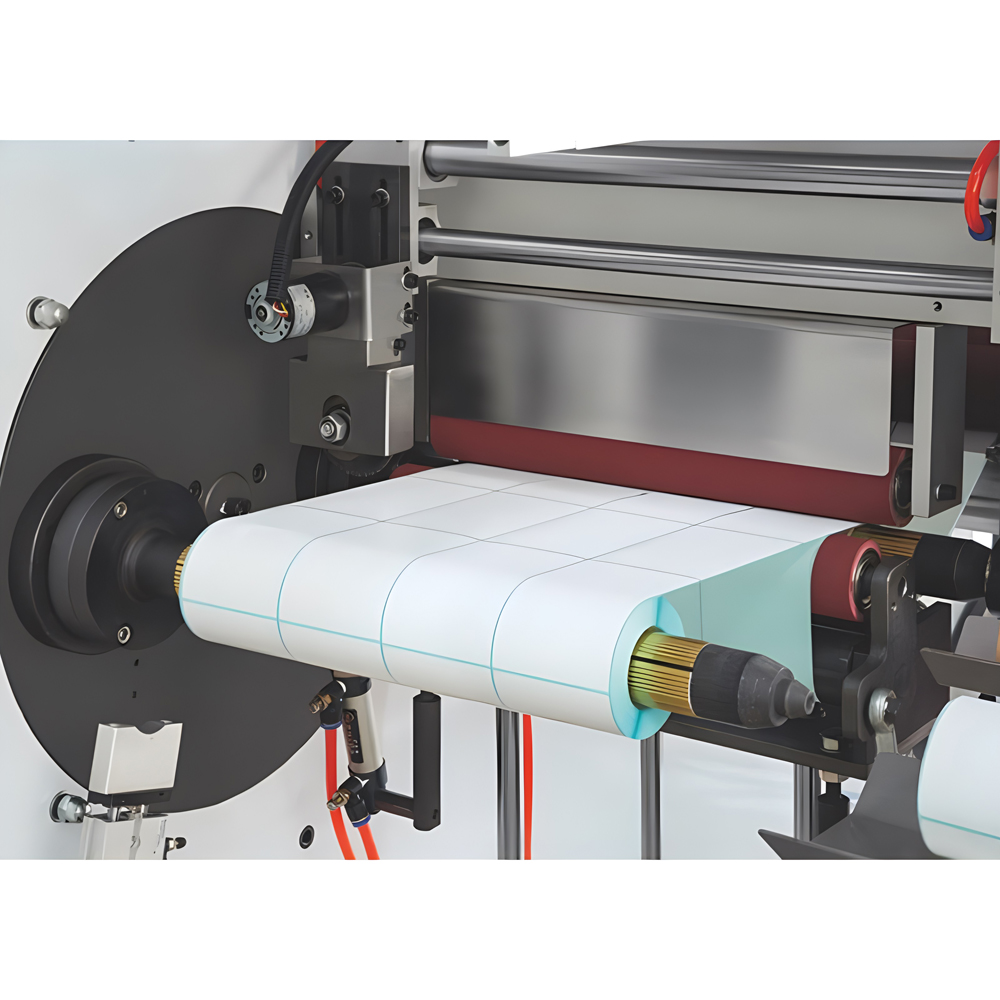

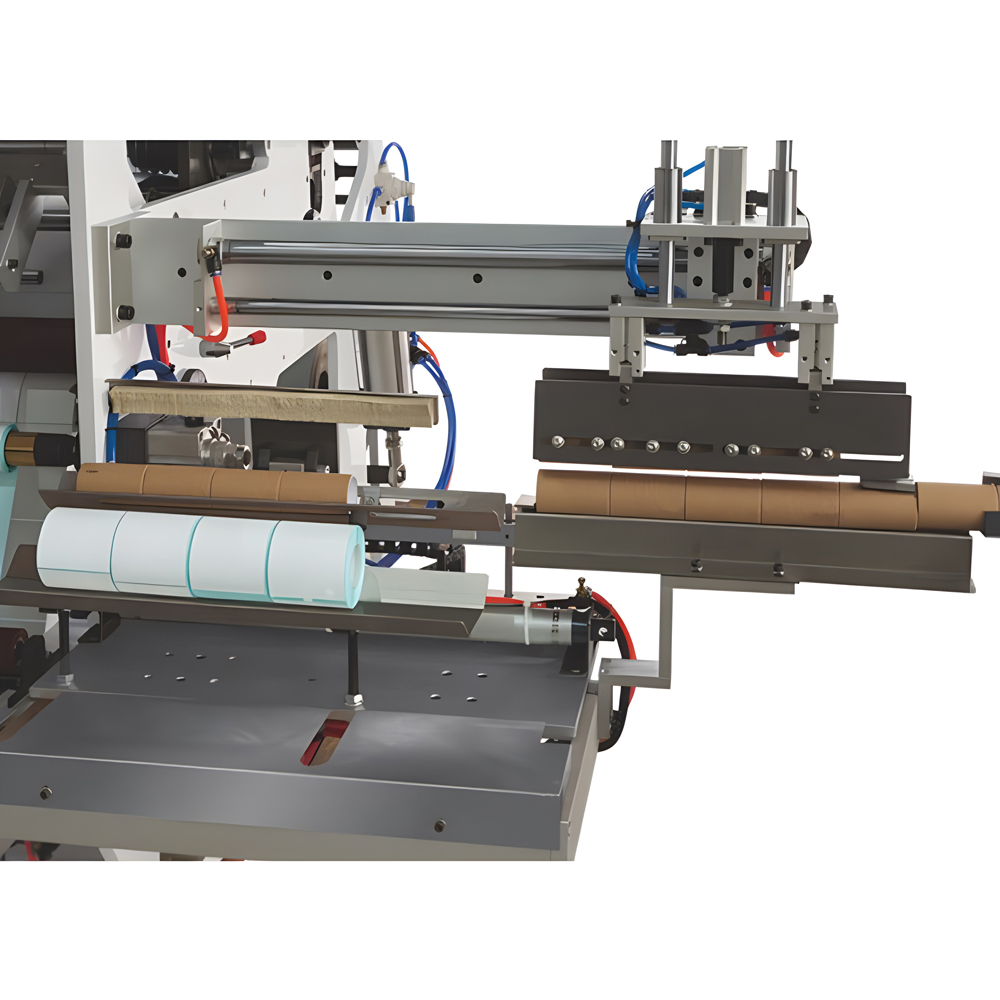

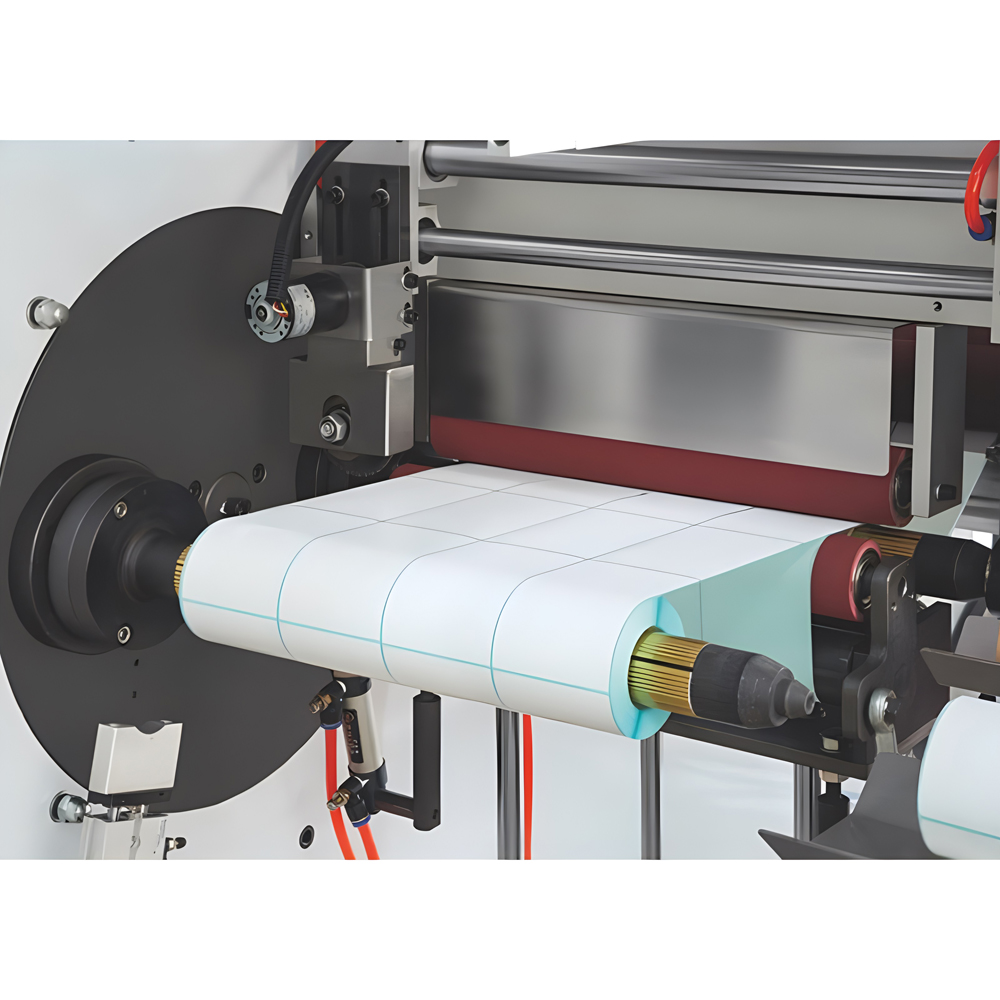

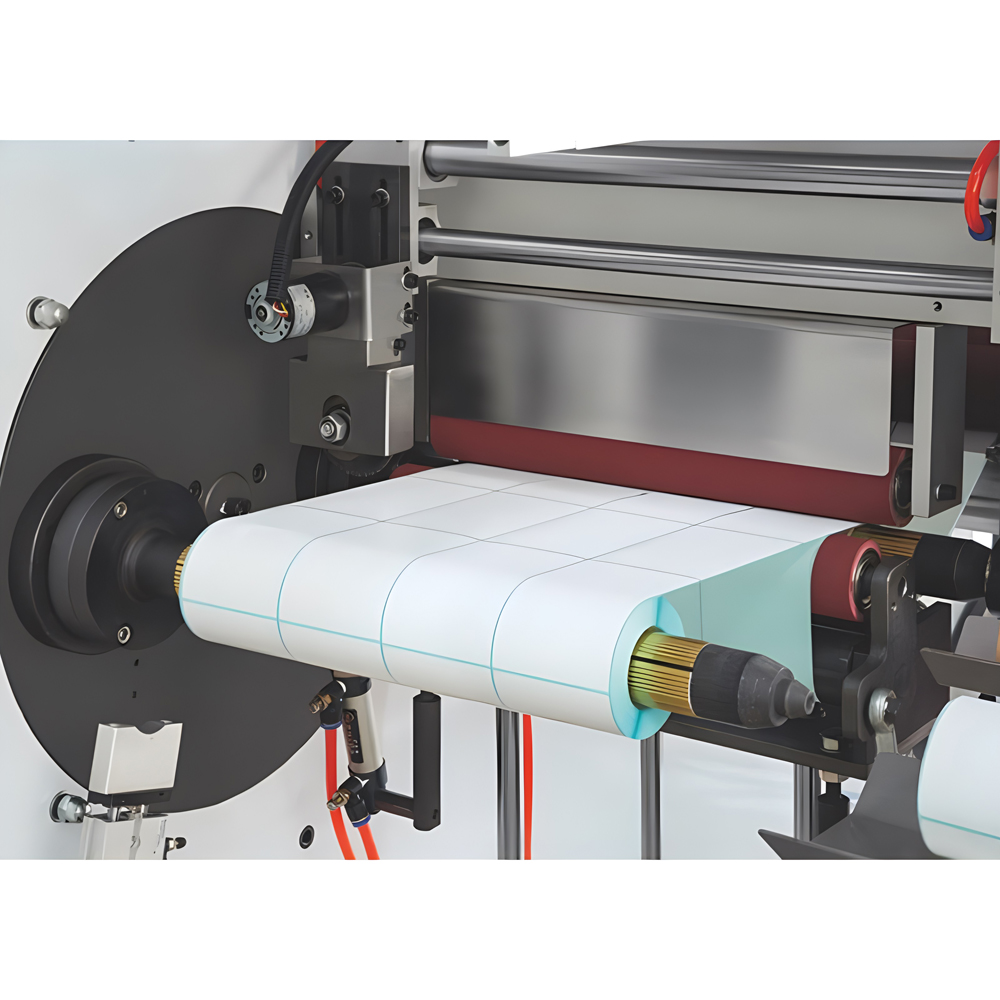

Adjustable Air Shafts: Four air shafts (2x40mm, 2x25mm) can be interchanged for different roll diameters, providing flexibility.

Seamless Labeling Unit: Automatically seals finished rolls, maintaining product integrity.

Precision Slitting Unit: Accurately cuts label material to the desired width for individual label production.

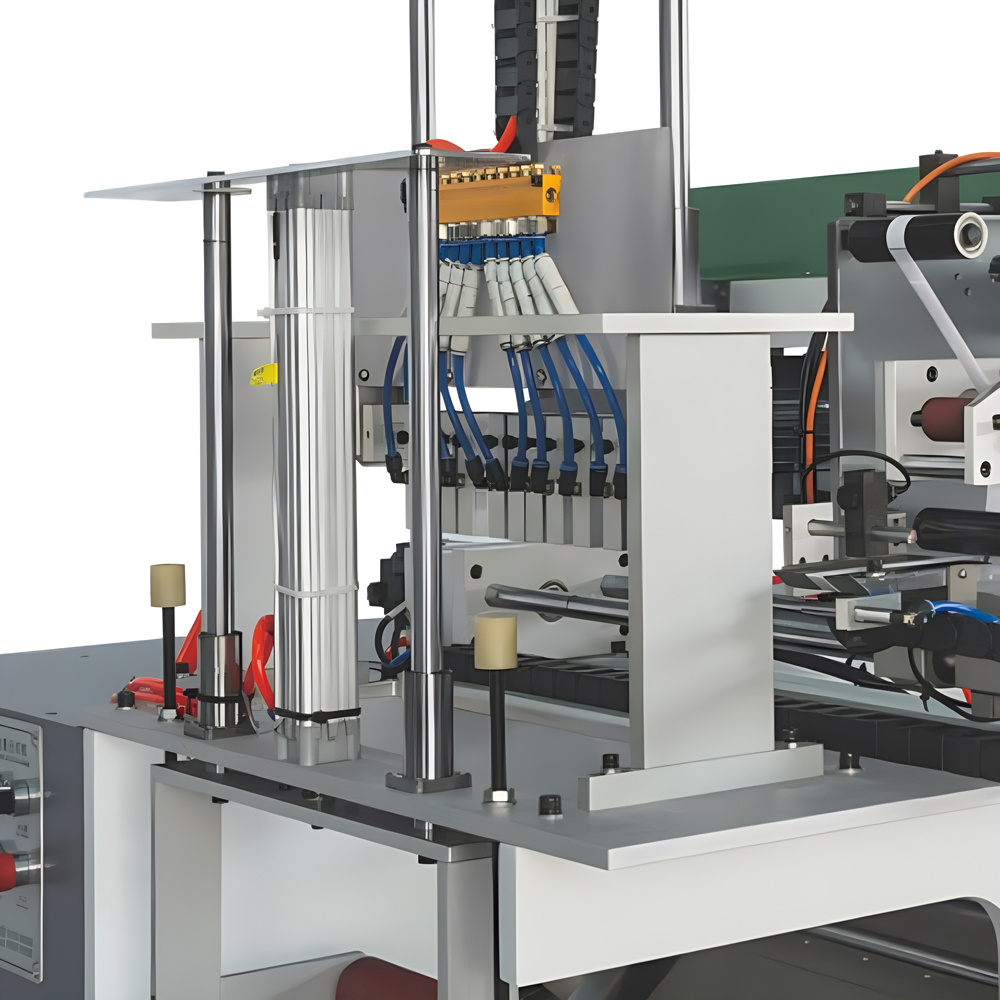

Advanced Die Cutting Unit: Capable of cutting intricate designs, enhancing label customization (Magnetic Cylinder sold separately).

Efficient Roll Delivery: Automatically delivers finished rolls in an organized manner for easy handling.

Intuitive Control System: PLC, servo motors, and a user-friendly touch screen interface for precise operation and adjustments.

Product Applications:

Ideal for label manufacturers, this machine is perfect for producing labels for various industries, including but not limited to packaging, pharmaceuticals, cosmetics, and food & beverage. Its versatility makes it suitable for a wide range of label materials and applications.

Product Transportation:

The machine is designed for easy transportation and setup. Detailed instructions are provided to ensure a smooth installation process. Additionally, protective measures are taken during shipping to safeguard the machine from potential damage.

Data Sheet:

| Max web width | 420mm |

| Max.speed | 220m/min |

| Max rewinding diameter | 140mm |

| Max. unwinding diameter | 800mm |

| Cutting precision | ±0.1 |

| Voltage | 380v,3phase 50hz |

| Mechanical speed | 220m/min |

| Overall Dimension | 1750*3000*2400 |

| Weight of Machine | 2000kg |

Machine detial:

Customer feedback: